Understanding Shrinkage Cracks in Concrete

Concrete is one of the most widely used construction materials globally, known for its strength, durability, and versatility. However, like any material, concrete is susceptible to various forms of deterioration over time, with cracking being one of the most common issues encountered. Among the different types of cracks that can occur in concrete, those resulting from shrinkage are particularly prevalent and require careful attention during design, construction, and maintenance phases.

What Causes Shrinkage Cracks?

Shrinkage cracks in concrete occur primarily due to the natural process of hydration and subsequent drying. When water is mixed with cement to form a paste, it chemically reacts to create a strong matrix that binds together aggregates. As this paste dries, water evaporates, causing the concrete to shrink. This shrinkage induces tensile stresses within the concrete, eventually leading to the formation of cracks as the material seeks relief.

Several factors can influence the extent of shrinkage and the likelihood of cracks, including:

- Water Content: A higher water-to-cement ratio in the concrete mix results in greater shrinkage upon drying. Therefore, controlling the water content is crucial in minimizing shrinkage.

- Cement Type: Different types of cement have varying shrinkage characteristics. Some supplementary cementitious materials, such as fly ash or slag, can help reduce shrinkage when incorporated into the mix.

- Aggregate Properties: Aggregates with high moisture content or expansive properties can contribute to increased shrinkage and cracking.

- Temperature and Humidity: Environmental conditions during curing and early age concrete development play a significant role. High temperatures and low humidity accelerate the drying process, leading to more pronounced shrinkage.

Detecting Shrinkage Cracks

Shrinkage cracks typically appear as thin, hairline cracks on the surface of concrete structures. They often follow a random pattern and may extend to varying depths depending on factors such as concrete mix design, curing methods, and environmental conditions. While shrinkage cracks are not usually indicative of structural failure, they can compromise the aesthetics and durability of concrete surfaces if left unaddressed.

Preventive Measures

Preventing shrinkage cracks requires a proactive approach encompassing various strategies:

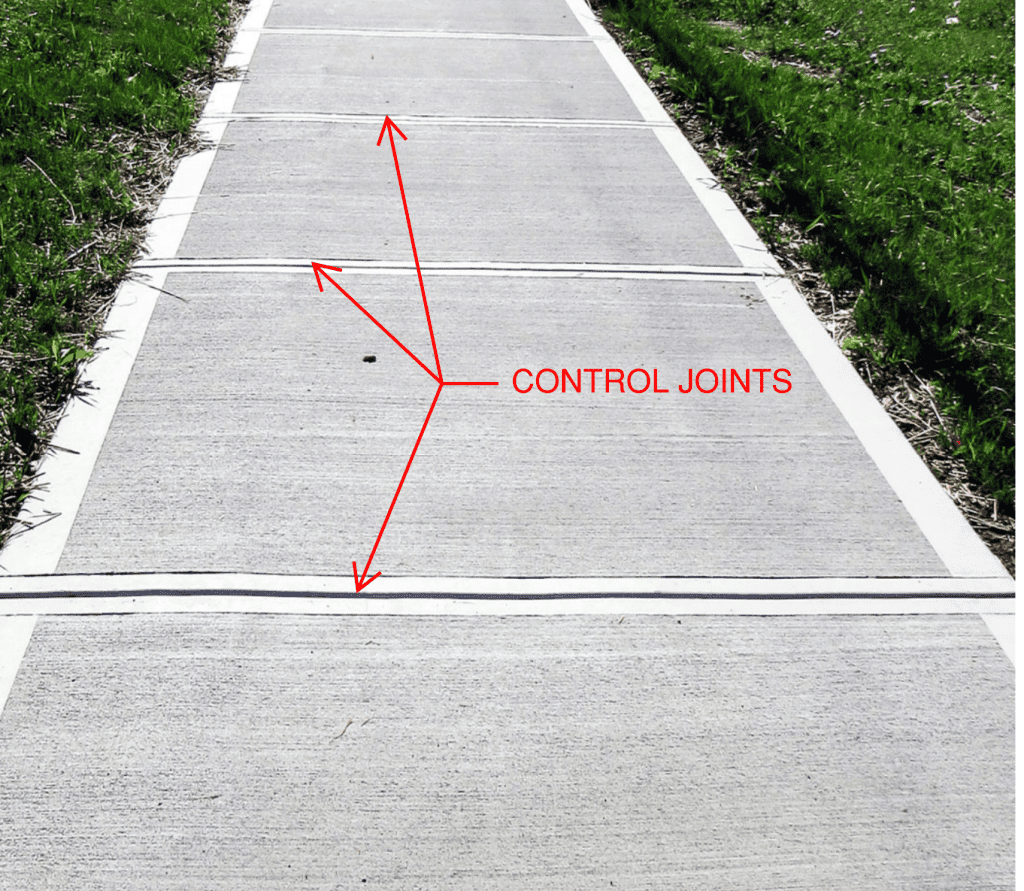

- Control Joints: Incorporating control joints, also known as contraction joints, into the concrete design provides predetermined locations for cracks to occur, thereby minimizing random cracking. Proper spacing and depth of control joints are critical in controlling shrinkage-induced stresses. The spacing, depth, and width of control joints should be determined based on factors such as slab thickness, anticipated shrinkage, and environmental conditions. In general, control joints are spaced at distances ranging from 24 to 36 times the slab thickness. For example, for a 4-inch thick slab, control joints might be spaced approximately every 8 to 12 feet.

- Optimized Mix Design: Selecting an appropriate concrete mix design with a low water-to-cement ratio and suitable supplementary materials can help mitigate shrinkage. Admixtures like shrinkage-reducing agents can also be used to minimize cracking.

- Curing Techniques: Implementing proper curing methods such as moist curing, curing compounds, or covering the concrete with wet materials helps maintain adequate moisture levels, reducing shrinkage.

- Avoiding Rapid Drying: Preventing rapid evaporation of moisture from the concrete surface by using windbreaks, shading, or temporary covers minimizes shrinkage.

- Quality Control: Ensuring quality throughout the construction process, from material selection to placement and finishing, is essential in minimizing the occurrence of shrinkage cracks.

Addressing Shrinkage Cracks

Despite preventive measures, shrinkage cracks may still develop in concrete structures. Prompt identification and repair of these cracks are essential to prevent further deterioration. Common repair methods include filling cracks with sealants, epoxy injections, or applying surface sealers to prevent moisture ingress.

Conclusion

Shrinkage cracks are a natural occurrence in concrete resulting from the drying process during hydration. While they may not always pose a structural risk, they can detract from the appearance and durability of concrete surfaces if not addressed properly. By implementing preventive measures and adopting appropriate repair techniques, engineers and contractors can minimize the impact of shrinkage cracks, ensuring the long-term performance of concrete structures.

Rishav Shrivastav (Structural Engineer)

Author

OTHER PHOTOS OF DAMAGED PLAIN CONCRETE ROADS