In this design article,

- You’ll understand the requirements of sand to be used in Slow sand/Rapid sand/Pressure filter.

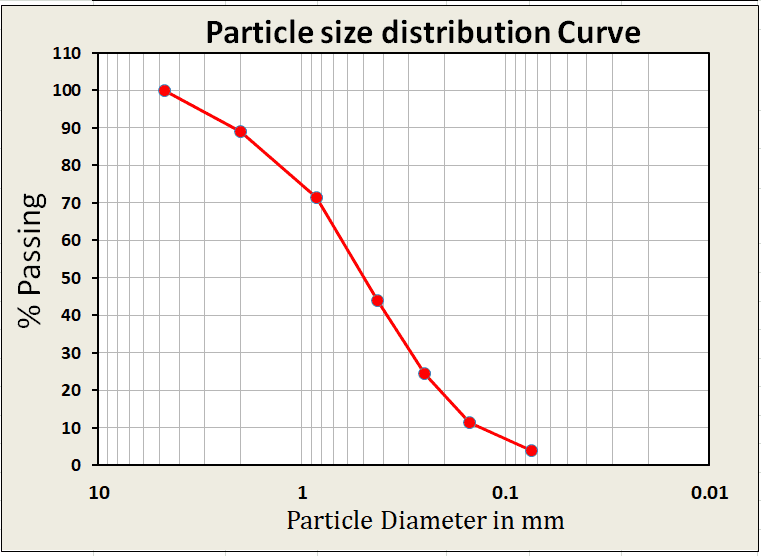

- AutoDraw the particle distribution curve

- AutoDesign the sand of the required effective diameter and coefficient of uniformity

It is not limited to the sand only, and you can design for soils and gravels also.

Now, let’s learn some basics.

Why sand preparation is necessary?

For the slow sand and rapid sand filter, the sand from the river cannot be used directly. The river sand may be too fine or too coarse and voids may not be uniformly graded. It needs to be prepared for the filter.

What are the major criteria needed for Filter Sand?

The most important criteria for preparing the sand to be used as a sand bed are its effective size and uniformity coefficient.

- Effective size (D10): It is the sieve size in mm from which 10% of the sand by weight can pass.

Example: If the sand stock has D10=0.5mm, then 10% of the sand is less than 0.5mm and 90% of the sand is greater than 0.5mm by weight.

- Uniformity coefficient (Cu): It is the ratio between the sieve size which will pass 60% of the sand by weight (D60) to the effective size (D10). Cu = D60/D10

What other criteria need to be looked at?

Other criteria also need to be fulfilled which are: (Source: IS 8419)

- Sand should be free of clay particles and should be hard quartz or quartzite.

- Ignition loss should not exceed 0.7% by weight.

- The soluble fraction in hydrochloric acid shall not exceed 5% by weight.

- Silica content should not be less than 90%.

- Wearing loss shall not exceed 3%

Usually, the river sand fulfills the other criteria and the sand should be prepared for the desired effective size and uniformity.

How to remove the too-fine and too-coarse sand?

The too-fine particles and too-coarse particles should be removed. It is done by:

- Too Fine: Washing out in a sand washer

- Too Coarse: Sieving out the coarse grains

Design of the Filter Sand?

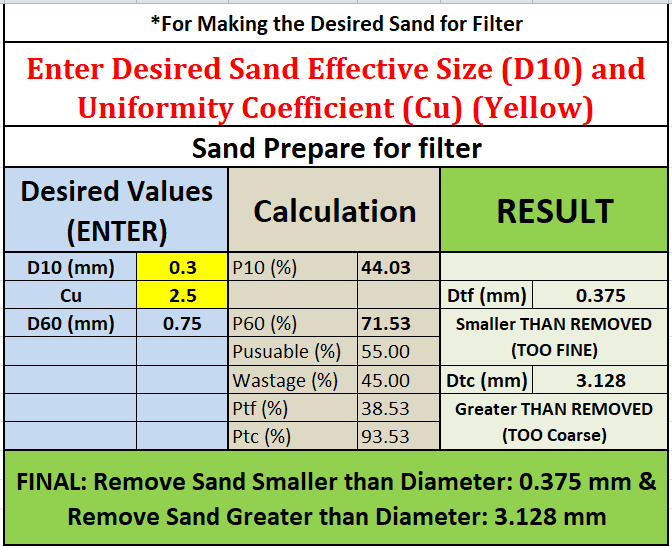

In summary, the design of the filter sand is given by the formula:

- Percentage Too Fine (Ptf) = 1.2P10 – 0.2 P60

- Percentage Too Coarse (Ptc) = 1.8P60 – 0.8 P10

- The Total Sand Used (Pusuable)= 2 (P60 – P10)

Where P10 is % of stocked sand smaller than the desired D10 size

P60 is % of stocked sand smaller than the desired D60 size

Now, the diameter of sand below Dtf and diameter of sand above Dtc need to be separated out. These diameters is determined from the graph plots.

| Description | Slow Sand Filter | Rapid Sand Filter |

| Effective Size (D10) | 0.2 – 0.3 mm | 0.45 – 0.7 mm |

| Uniformity coefficient (Cu) | 3.0 – 5.0 | 1.3 – 1.7 |

High values of Cu mean well-graded soil. This means there are less voids.

If Cu=1, it means D60/D10 =1. This means all sand consists of only one size.

From this, we can see that:

- Slow sand filter’s effective diameter is less and the high Cu indicates there are less voids.

- Whereas, for rapid sand filter the effective size is also high and a low Cu indicates more voids.

NOW, LETS SEE HOW TO DESIGN THE DESIRED SAND FROM STOCK SAND

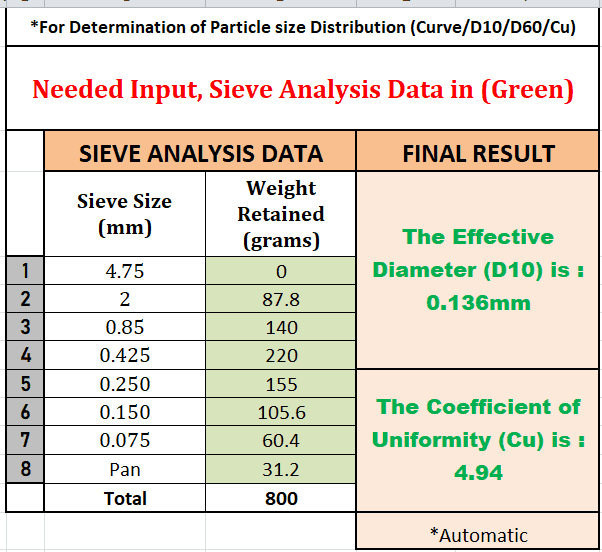

STEP 1: Enter the weight of the sand from the sieve analysis.

You will get the effective size (D10) and coefficient of uniformity of sand (Cu)

The size of the sieve can also be changed but maximum is 8 nos of sieve including the pan.

Automatic particle size distribution curve is drawn

Step 2: Enter the desired value of the effective size (D10) and coefficient of uniformity of sand (Cu)

You’ll get the sand diameter which is too fine and too coarse and needs to be removed.

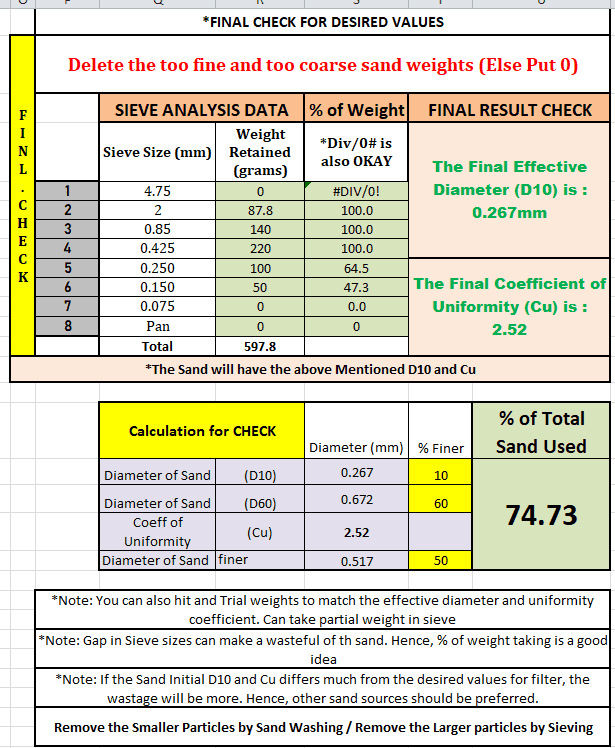

Step 3: Delete the weights of the fine sand and coarse sand as determined previously.

You’ll get the final effective diameter and coefficient of uniformity of the sand. The total percentage of initial sand used is also given.

You may do the hit and trial to keep some portion of the fine and coarse sand and get the outputs.

Now, you can perform your calculations.

- You can zoom In/out. Refresh the page to get initial values.

Note: You can zoom in/out

*Disclaimer: The author is not responsible for professional or any use of this design sheet.